Deepening Market Insights|Accordance × FlowDynamic Project Warsaw Industry Week Post-Show Report Reveals the Next Step of Poland's Smart Manufacturing Transformation

Market Pulse: Rising Smart Manufacturing Demand and Urgent Need for Data Integration

This year’s Warsaw Industry Week placed strong emphasis on automation, system integration, and intelligent factory innovations. Manufacturing companies on-site expressed similar challenges—including workforce shortages, extended reaction times to production anomalies, and difficulties integrating data across OT/IT systems. Many visitors also shared concerns about managing multi-site equipment, cross-plant monitoring, and improving operational resilience.

Accordance and FlowDynamic Project observed a clear shift in the Polish market: manufacturers are moving from basic equipment automation toward data-driven intelligent management. Beyond equipment performance, companies are prioritizing cross-system data coordination and real-time visibility for decision-making. This emerging trend forms a crucial foundation for the partners’ future local collaboration and solution deployment.

Exhibition Highlights: Strong Visitor Engagement and In-Depth Technical Discussions

Accordance’s booth remained vibrant across all three exhibition days. Professionals from various manufacturing sectors continuously approached the team to explore new use cases in data automation and centralized management. After learning about the system architecture, many visitors initiated detailed discussions based on their actual production workflows—covering process configuration, data flow design, cross-system integration, and monitoring strategies. What began as product introductions frequently evolved into deep technical conversations centered on real operational pain points.

Additionally, remote monitoring, multi-device centralized control, and no-code integration tools attracted significant interest. Accordance and FlowDynamic Project also received a substantial number of follow-up technical inquiries, with the exhibition driving strong cross-border engagement and initiating further contact for multiple potential collaborations.

Technology Showcase: ARAID, RCVM, and AiRPA Present a Complete Path From Device Security to Data-Driven Decisions

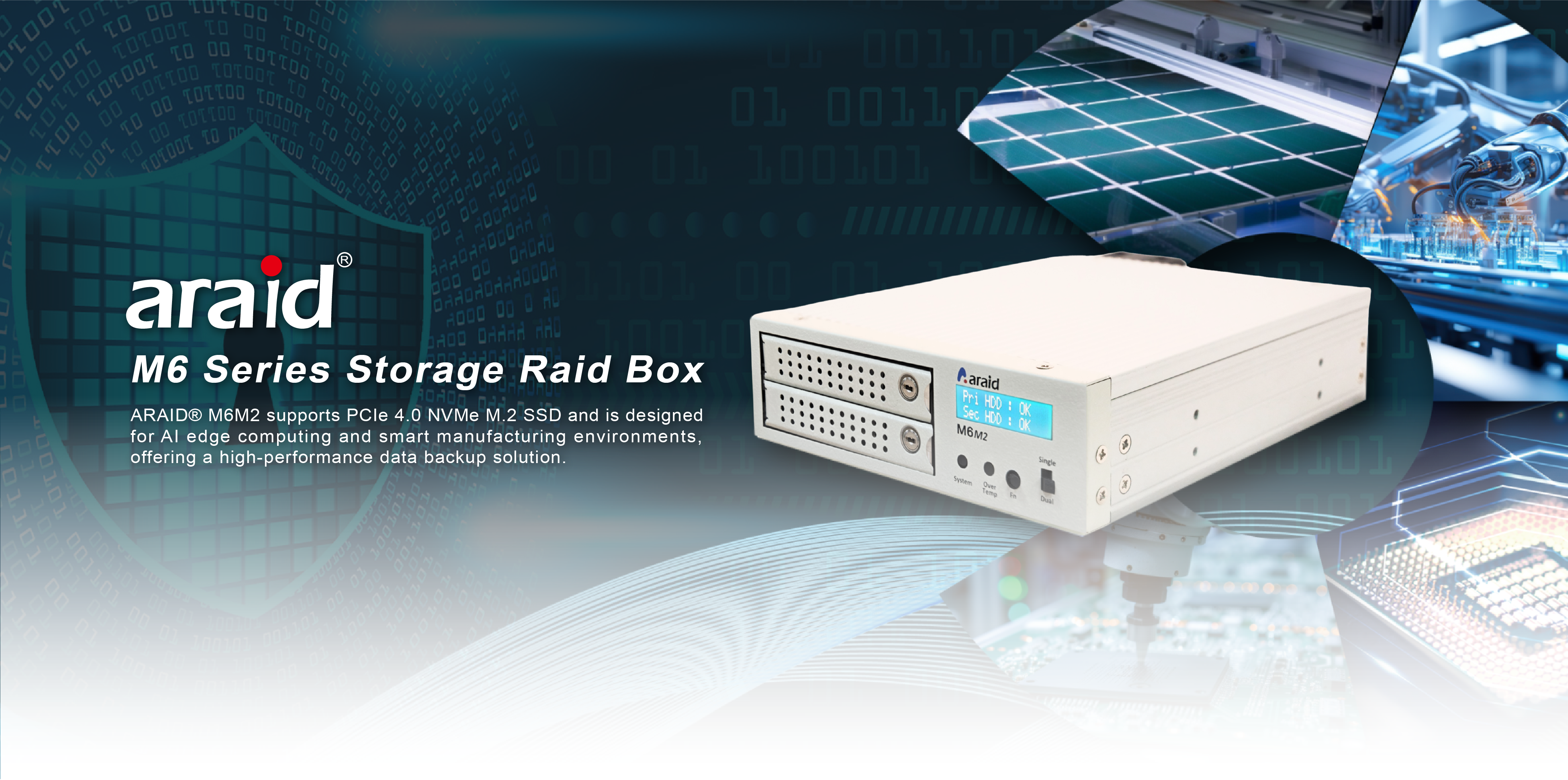

The joint showcase featured three key solutions: ARAID industrial-grade data protection storage, RCVM remote centralized management, and AiRPA smart process automation.

ARaid delivers device-level data protection and operational stability, addressing local manufacturing needs for reliability and secure equipment performance. RCVM’s multi-perspective centralized monitoring architecture supports cross-factory visibility and rapid anomaly response, while remaining compatible with existing systems. AiRPA enables end-to-end workflow automation—covering data collection, report generation, and system operations—without programming, allowing factories to enhance efficiency through a “digital workforce.”

Together, these technologies demonstrate a complete vertical capability—from equipment safety to data orchestration and intelligent decision-making—drawing strong interest in integration feasibility and deployment models.

Strengthening Presence in Poland Through Local Partnership

The exhibition allowed Accordance and FlowDynamic Project to gain deeper insights into Poland’s digital transformation needs and to refine joint strategies for local deployment, service support, and value-chain collaboration. As Central and Eastern Europe accelerates industrial modernization, the importance of data automation, centralized monitoring, and cross-system integration continues to rise.

The post-show results confirm that Poland is becoming a strategic hub for smart manufacturing and industrial technologies. With complementary strengths, Accordance and FlowDynamic Project are well-positioned to support manufacturers in advancing toward the next stage of intelligent transformation.

[Accordance & FlowDynamic Project]