- Home

- Industries

- Manufacturing

Manufacturing

The Widespread Adoption of AI and Robotics

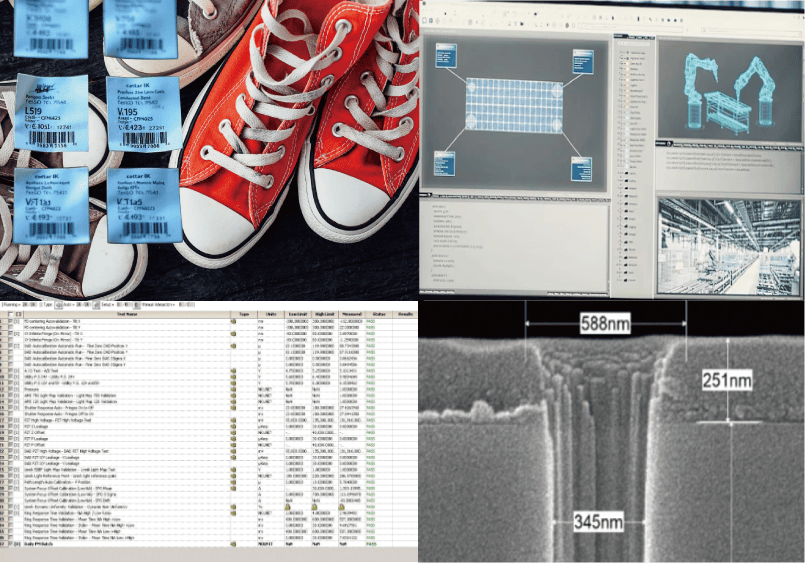

AI is evolving from a supporting tool in manufacturing to a core technology. Increasingly, industries are incorporating it into daily operations — from product inspection and voice recognition to intelligent decision-making — significantly improving efficiency and accuracy.

By integrating Robotic Process Automation (RPA), businesses can automate large volumes of repetitive tasks, such as data entry and process control, reducing labor costs and minimizing errors.

The synergy of AI and RPA not only enhances operational efficiency but also drives unprecedented digital transformation across manufacturing, finance, customer service, and healthcare sectors.

Industrial Internet of Things (IIoT) and Edge Computing

The IIoT connects sensors, machines, and equipment, enabling real-time data collection, transmission, and analysis on the factory floor. This enables intelligent monitoring, predictive maintenance, and process optimization.

Today, the shift from cloud to edge computing allows data processing closer to the devices or sensors, rather than sending all data to centralized cloud servers.

This reduces latency, enhances system stability and responsiveness, and enables more agile and efficient factories — accelerating the path toward smart manufacturing and digital transformation.

Sustainability and ESG Practices

Companies are placing greater emphasis on Environmental, Social, and Governance (ESG) goals. Through smart manufacturing technologies, they aim to improve energy efficiency, reduce carbon footprints, and promote resource circularity, aligning with global trends in green manufacturing.

Industry Pain Points

1.Difficulty in Data Integration

- Inconsistent data formats due to diverse equipment, system brands, and outdated technologies.

- Lack of a unified platform for integrating production line data.

2.Aging Equipment Hinders Digitalization

- Many machines cannot connect to the internet directly and require additional sensors or edge devices.

- High equipment upgrade costs often result in poor return on investment (ROI).

3.High Implementation Costs and ROI Uncertainty

- Initial investment is substantial, covering sensors, network infrastructure, platform software, and employee training.

- Benefits are difficult to quantify, leading to hesitation or lack of confidence from senior management.

4.Talent Shortage - Lack of talent with both IT and OT expertise.

- Misalignment between compensation and job roles leads to employee resistance to change; upskilling or retraining is often required.

5.Network and Cybersecurity Issues - Once connected to the network, production equipment becomes vulnerable to cyber threats such as hacking and ransomware.

- Traditional industrial control systems lack built-in security, making them easy targets.

Solutions

| Product / Solution | Features & Highlights | Addressed Pain Points | Resolved Challenges |

|---|---|---|---|

| ARAID® RAID Enclosure | High-speed backup and instant recovery, ensuring uninterrupted operation | High risk of data loss, slow backup speed | Establish a reliable operational foundation with disaster recovery mechanism |

| AiRPA Robotic Process Automation | Integrated with OCR text recognition & remote control, script-based workflow automation, improving human-to-machine ratio | High manual error rate, repetitive labor consumption | Implement automation to reduce downtime and minimize production disruption |

| PLC+ Remote Control and Data Collection Solution | Smart integration with legacy PLC devices, supporting multiple communication protocols | Outdated equipment with no data output capability | Industrial 4.0 upgrade, enhancing data visibility |

| RCVM Remote Monitoring Solutions | Remote monitoring of real-time machine status, troubleshooting, maintenance support, and operational analysis | Decentralized plant management, delayed abnormal event handling | Integrated large-scale site management, improving equipment utilization and decision-making efficiency |

Application Scenarios

Conclusion

In the wave of smart manufacturing, companies must actively adopt automation, digitalization, and intelligent solutions to remain competitive. Accordance offers essential technologies for smart factories — including data backup, robotic automation, legacy PLC upgrades, and remote monitoring and management. Partnering with Accordance is not just a technological upgrade, but a decisive step toward sustainable development and digital transformation.

RELATED PRODUCTS

Associated News